in order for combustion to occur what needs to happen

The flames caused as a upshot of a fuel undergoing combustion (burning)

Combustion, or burning,[1] is a high-temperature exothermic redox chemical reaction betwixt a fuel (the reductant) and an oxidant, ordinarily atmospheric oxygen, that produces oxidized, ofttimes gaseous products, in a mixture termed as smoke. Combustion does not always event in burn down, because a flame is only visible when substances undergoing combustion vaporize, only when it does, a flame is a characteristic indicator of the reaction. While the activation free energy must be overcome to initiate combustion (eastward.g., using a lit match to lite a fire), the rut from a flame may provide enough energy to make the reaction self-sustaining.

Combustion is often a complicated sequence of elementary radical reactions. Solid fuels, such every bit forest and coal, first undergo endothermic pyrolysis to produce gaseous fuels whose combustion so supplies the rut required to produce more of them. Combustion is oft hot enough that incandescent light in the form of either glowing or a flame is produced. A simple example can be seen in the combustion of hydrogen and oxygen into h2o vapor, a reaction commonly used to fuel rocket engines. This reaction releases 242kJ/mol of heat and reduces the enthalpy accordingly (at constant temperature and pressure level):

- 2H

2 (g) + O

2 (chiliad) → twoH2O(grand)

Combustion of an organic fuel in air is ever exothermic because the double bail in O2 is much weaker than other double bonds or pairs of single bonds, and therefore the formation of the stronger bonds in the combustion products CO2 and H2O results in the release of energy.[2] The bond energies in the fuel play only a minor part, since they are similar to those in the combustion products; east.g., the sum of the bond energies of CHiv is nearly the same every bit that of CO2. The heat of combustion is approximately −418 kJ per mole of Otwo used upwards in the combustion reaction, and tin can be estimated from the elemental composition of the fuel.[2]

Uncatalyzed combustion in air requires relatively high temperatures. Complete combustion is stoichiometric concerning the fuel, where at that place is no remaining fuel, and ideally, no remainder oxidant. Thermodynamically, the chemical equilibrium of combustion in air is overwhelmingly on the side of the products. Nevertheless, complete combustion is almost impossible to achieve, since the chemical equilibrium is not necessarily reached, or may contain unburnt products such as carbon monoxide, hydrogen and even carbon (soot or ash). Thus, the produced smoke is commonly toxic and contains unburned or partially oxidized products. Any combustion at loftier temperatures in atmospheric air, which is 78 percent nitrogen, will also create small amounts of several nitrogen oxides, commonly referred to as NOx, since the combustion of nitrogen is thermodynamically favored at high, but not low temperatures. Since burning is rarely make clean, fuel gas cleaning or catalytic converters may be required by constabulary.

Fires occur naturally, ignited by lightning strikes or by volcanic products. Combustion (fire) was the first controlled chemical reaction discovered past humans, in the form of campfires and bonfires, and continues to be the main method to produce energy for humanity. Ordinarily, the fuel is carbon, hydrocarbons, or more complicated mixtures such as woods that contains partially oxidized hydrocarbons. The thermal energy produced from combustion of either fossil fuels such equally coal or oil, or from renewable fuels such as firewood, is harvested for diverse uses such every bit cooking, production of electricity or industrial or domestic heating. Combustion is likewise currently the only reaction used to ability rockets. Combustion is also used to destroy (incinerate) waste, both nonhazardous and hazardous.

Oxidants for combustion accept high oxidation potential and include atmospheric or pure oxygen, chlorine, fluorine, chlorine trifluoride, nitrous oxide and nitric acid. For instance, hydrogen burns in chlorine to grade hydrogen chloride with the liberation of oestrus and light characteristic of combustion. Although usually non catalyzed, combustion tin can be catalyzed past platinum or vanadium, as in the contact process.

Types [edit]

Complete and incomplete [edit]

Complete [edit]

In consummate combustion, the reactant burns in oxygen and produces a limited number of products. When a hydrocarbon burns in oxygen, the reaction will primarily yield carbon dioxide and h2o. When elements are burned, the products are primarily the about common oxides. Carbon volition yield carbon dioxide, sulfur will yield sulfur dioxide, and iron will yield iron(III) oxide. Nitrogen is not considered to be a combustible substance when oxygen is the oxidant. Notwithstanding, small amounts of various nitrogen oxides (normally designated NO

ten species) form when the air is the oxidative.

Combustion is not necessarily favorable to the maximum degree of oxidation, and it can exist temperature-dependent. For instance, sulfur trioxide is not produced quantitatively past the combustion of sulfur. NOx species appear in pregnant amounts above about two,800 °F (1,540 °C), and more is produced at higher temperatures. The amount of NOx is also a function of oxygen excess.[three]

In nearly industrial applications and in fires, air is the source of oxygen (O

2 ). In the air, each mole of oxygen is mixed with approximately 3.71 mol of nitrogen. Nitrogen does not take function in combustion, but at high temperatures some nitrogen will be converted to NO

10 (mostly NO, with much smaller amounts of NO

ii ). On the other hand, when there is insufficient oxygen to combust the fuel completely, some fuel carbon is converted to carbon monoxide, and some of the hydrogens remain unreacted. A complete ready of equations for the combustion of a hydrocarbon in the air, therefore, requires an boosted calculation for the distribution of oxygen between the carbon and hydrogen in the fuel.

The amount of air required for complete combustion to take place is known as pure air[ citation needed ]. However, in practice, the air used is ii-three times that of pure air.

Incomplete [edit]

Incomplete combustion will occur when at that place is not enough oxygen to allow the fuel to react completely to produce carbon dioxide and water. Information technology as well happens when the combustion is quenched by a oestrus sink, such every bit a solid surface or flame trap. As is the instance with consummate combustion, h2o is produced by incomplete combustion; however, carbon, carbon monoxide, and hydroxide are produced instead of carbon dioxide.

For most fuels, such as diesel oil, coal, or wood, pyrolysis occurs before combustion. In incomplete combustion, products of pyrolysis remain unburnt and contaminate the smoke with baneful particulate matter and gases. Partially oxidized compounds are also a concern; partial oxidation of ethanol can produce harmful acetaldehyde, and carbon can produce toxic carbon monoxide.

The designs of combustion devices can ameliorate the quality of combustion, such every bit burners and internal combustion engines. Further improvements are achievable by catalytic subsequently-burning devices (such as catalytic converters) or past the elementary partial return of the exhaust gases into the combustion process. Such devices are required by ecology legislation for cars in most countries. They may be necessary to enable large combustion devices, such as thermal ability stations, to achieve legal emission standards.

The caste of combustion can be measured and analyzed with test equipment. HVAC contractors, firefighters and engineers use combustion analyzers to examination the efficiency of a burner during the combustion procedure. Also, the efficiency of an internal combustion engine can be measured in this way, and some U.S. states and local municipalities use combustion assay to ascertain and charge per unit the efficiency of vehicles on the road today.

Incomplete combustion produced carbon monoxide [edit]

Carbon monoxide is one of the products from incomplete combustion.[4] Carbon is released in the normal incomplete combustion reaction, forming soot and dust. Since carbon monoxide is a poisonous gas, consummate combustion is preferable, as carbon monoxide may besides atomic number 82 to respiratory troubles when breathed since it takes the place of oxygen and combines with hemoglobin.[5]

Problems associated with incomplete combustion [edit]

- Environmental problems:[6]

These oxides combine with water and oxygen in the temper, creating nitric acrid and sulfuric acids, which return to Globe'southward surface as acid deposition, or "acrid rain." Acrid deposition harms aquatic organisms and kills trees. Due to its formation of sure nutrients that are less available to plants such equally calcium and phosphorus, information technology reduces the productivity of the ecosystem and farms. An additional problem associated with nitrogen oxides is that they, along with hydrocarbon pollutants, contribute to the formation of ground level ozone, a major component of smog.

- Human wellness bug:[6]

Breathing carbon monoxide causes headache, dizziness, vomiting, and nausea. If carbon monoxide levels are high plenty, humans become unconscious or die. Exposure to moderate and high levels of carbon monoxide over long periods is positively correlated with risk of heart disease. People who survive severe carbon monoxide poisoning may endure long-term health problems.[7] Carbon monoxide from air is absorbed in the lungs which then binds with hemoglobin in human's red blood cells. This would reduce the chapters of red blood cells to carry oxygen throughout the body.

Smouldering [edit]

Smouldering is the slow, low-temperature, flameless class of combustion, sustained by the rut evolved when oxygen directly attacks the surface of a condensed-phase fuel. Information technology is a typically incomplete combustion reaction. Solid materials that tin sustain a smouldering reaction include coal, cellulose, forest, cotton, tobacco, peat, duff, humus, synthetic foams, charring polymers (including polyurethane foam) and grit. Common examples of smoldering phenomena are the initiation of residential fires on upholstered article of furniture by weak rut sources (eastward.chiliad., a cigarette, a short-circuited wire) and the persistent combustion of biomass behind the flaming fronts of wildfires.

Rapid [edit]

An experiment that demonstrates the big amount of energy released on combustion of ethanol. A mixture of alcohol (in this example, ethanol) vapour and air in a large plastic canteen with a small neck is ignited, resulting in a large blue flame and a 'whoosh' sound.

Rapid combustion is a form of combustion, otherwise known equally a burn, in which large amounts of estrus and light energy are released, which oft results in a flame. This is used in a class of machinery such as internal combustion engines and in thermobaric weapons. Such a combustion is oft chosen a Rapid combustion, though for an internal combustion engine this is inaccurate.[ disputed ] An internal combustion engine nominally operates on a controlled rapid burn. When the fuel-air mixture in an internal combustion engine explodes, that is known as detonation.[ disputed ]

Spontaneous [edit]

Spontaneous combustion is a type of combustion which occurs by self-heating (increase in temperature due to exothermic internal reactions), followed by thermal delinquent (cocky-heating which chop-chop accelerates to loftier temperatures) and finally, ignition. For case, phosphorus cocky-ignites at room temperature without the awarding of heat. Organic materials undergoing bacterial composting can generate enough heat to reach the point of combustion.[eight]

Turbulent [edit]

Combustion resulting in a turbulent flame is the most used for industrial application (due east.g. gas turbines, gasoline engines, etc.) because the turbulence helps the mixing process between the fuel and oxidizer.

Micro-gravity [edit]

Colourized gray-calibration composite image of the individual frames from a video of a backlit fuel droplet called-for in microgravity.

The term 'micro' gravity refers to a gravitational state that is 'low' (i.e., 'micro' in the sense of 'modest' and non necessarily a millionth of Earth'southward normal gravity) such that the influence of buoyancy on physical processes may exist considered modest relative to other flow processes that would be nowadays at normal gravity. In such an environment, the thermal and period ship dynamics tin comport quite differently than in normal gravity conditions (e.g., a candle's flame takes the shape of a sphere.[9]). Microgravity combustion inquiry contributes to the understanding of a wide variety of aspects that are relevant to both the environment of a spacecraft (e.thousand., burn dynamics relevant to coiffure safety on the International Space Station) and terrestrial (Earth-based) atmospheric condition (e.g., droplet combustion dynamics to help developing new fuel blends for improved combustion, materials fabrication processes, thermal management of electronic systems, multiphase flow humid dynamics, and many others).

Micro-combustion [edit]

Combustion processes which happen in very small volumes are considered micro-combustion. The high surface-to-volume ratio increases specific rut loss. Quenching distance plays a vital part in stabilizing the flame in such combustion chambers.

Chemical equations [edit]

Stoichiometric combustion of a hydrocarbon in oxygen [edit]

Generally, the chemical equation for stoichiometric combustion of a hydrocarbon in oxygen is:

where .

For example, the stoichiometric burning of propane in oxygen is:

Stoichiometric combustion of a hydrocarbon in air [edit]

If the stoichiometric combustion takes place using air as the oxygen source, the nitrogen present in the air (Temper of Earth) can be added to the equation (although it does not react) to prove the stoichiometric limerick of the fuel in air and the composition of the resultant flue gas. Annotation that treating all non-oxygen components in air equally nitrogen gives a 'nitrogen' to oxygen ratio of iii.77, i.due east. (100% - O2%) / O2% where O2% is twenty.95% vol:

where .

For example, the stoichiometric combustion of propane ( ) in air is:

The stoichiometric limerick of propane in air is 1 / (ane + 5 + 18.87) = four.02% vol.

The stoichiometric combustion reaction for CαHβOγ in air:

The stoichiometric combustion reaction for CαHβOγSδ:

The stoichiometric combustion reaction for CαHβOγNδSouthwardε:

The stoichiometric combustion reaction for CαHβOγFδ:

Trace combustion products [edit]

Various other substances begin to appear in significant amounts in combustion products when the flame temperature is to a higher place about 1600 M. When backlog air is used, nitrogen may oxidize to NO and, to a much lesser extent, to NO

ii . CO forms by disproportionation of COtwo, and H

ii and OH form by disproportionation of HiiO.

For instance, when 1 mol of propane is burned with 28.half-dozen mol of air (120% of the stoichiometric corporeality), the combustion products contain 3.three% O

two . At 1400 M, the equilibrium combustion products contain 0.03% NO and 0.002% OH. At 1800 K, the combustion products contain 0.17% NO, 0.05% OH, 0.01% CO, and 0.004% H

2 .[ten]

Diesel engines are run with an backlog of oxygen to combust pocket-sized particles that tend to course with only a stoichiometric amount of oxygen, necessarily producing nitrogen oxide emissions. Both the U.s. and European Union enforce limits to vehicle nitrogen oxide emissions, which necessitate the use of special catalytic converters or treatment of the frazzle with urea (run across Diesel exhaust fluid).

Incomplete combustion of a hydrocarbon in oxygen [edit]

The incomplete (partial) combustion of a hydrocarbon with oxygen produces a gas mixture containing mainly CO

two , CO, H2O, and H

two . Such gas mixtures are usually prepared for employ as protective atmospheres for the heat-treatment of metals and for gas carburizing.[11] The general reaction equation for incomplete combustion of one mole of a hydrocarbon in oxygen is:

When z falls below roughly 50% of the stoichiometric value, CH

4 can become an important combustion product; when z falls beneath roughly 35% of the stoichiometric value, elemental carbon may become stable.

The products of incomplete combustion can be calculated with the help of a material residuum, together with the assumption that the combustion products reach equilibrium.[12] [13] For example, in the combustion of one mole of propane (C

three H

viii ) with four moles of O

2 , seven moles of combustion gas are formed, and z is 80% of the stoichiometric value. The iii elemental balance equations are:

These three equations are insufficient in themselves to calculate the combustion gas composition. However, at the equilibrium position, the water-gas shift reaction gives another equation:

- ;

For example, at 1200 K the value of Keq is 0.728.[14] Solving, the combustion gas consists of 42.4% HtwoO, 29.0% CO2, 14.seven% H

2 , and xiii.nine% CO. Carbon becomes a stable phase at 1200 One thousand and 1 atm pressure when z is less than 30% of the stoichiometric value, at which point the combustion products contain more than than 98% H

ii and CO and about 0.5% CH

4 .

Substances or materials which undergo combustion are called fuels. The about common examples are natural gas, propane, kerosene, diesel, petrol, charcoal, coal, wood, etc.

Liquid fuels [edit]

Combustion of a liquid fuel in an oxidizing atmosphere actually happens in the gas stage. It is the vapor that burns, not the liquid. Therefore, a liquid will unremarkably catch fire only higher up a sure temperature: its flash signal. The flash point of a liquid fuel is the lowest temperature at which it can form an ignitable mix with air. It is the minimum temperature at which there is plenty evaporated fuel in the air to start combustion.

Gaseous fuels [edit]

Combustion of gaseous fuels may occur through one of four distinctive types of burning: diffusion flame, premixed flame, autoignitive reaction forepart, or as a detonation.[fifteen] The type of burning that actually occurs depends on the degree to which the fuel and oxidizer are mixed prior to heating: for example, a improvidence flame is formed if the fuel and oxidizer are separated initially, whereas a premixed flame is formed otherwise. Similarly, the type of called-for likewise depends on the pressure: a detonation, for example, is an autoignitive reaction front end coupled to a strong daze wave giving it its feature high-pressure level tiptop and high detonation velocity.[xv]

Solid fuels [edit]

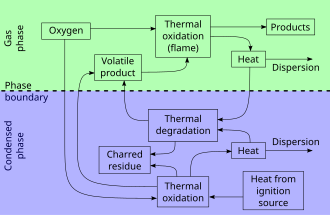

A full general scheme of polymer combustion

The human action of combustion consists of three relatively distinct just overlapping phases:

- Preheating phase, when the unburned fuel is heated upwardly to its flash point and and so fire bespeak. Flammable gases start existence evolved in a process similar to dry distillation.

- Distillation phase or gaseous phase, when the mix of evolved flammable gases with oxygen is ignited. Energy is produced in the form of estrus and light. Flames are ofttimes visible. Heat transfer from the combustion to the solid maintains the evolution of flammable vapours.

- Charcoal stage or solid stage, when the output of flammable gases from the material is too low for persistent presence of flame and the charred fuel does not burn down rapidly and but glows and later only smoulders.

Combustion management [edit]

Efficient process heating requires recovery of the largest possible function of a fuel's oestrus of combustion into the cloth being processed.[16] [17] At that place are many avenues of loss in the operation of a heating process. Typically, the ascendant loss is sensible heat leaving with the offgas (i.eastward., the flue gas). The temperature and quantity of offgas indicates its heat content (enthalpy), and so keeping its quantity depression minimizes heat loss.

In a perfect furnace, the combustion air period would be matched to the fuel catamenia to give each fuel molecule the verbal corporeality of oxygen needed to crusade complete combustion. However, in the real globe, combustion does not go along in a perfect manner. Unburned fuel (usually CO and H

two ) discharged from the organisation represents a heating value loss (every bit well as a safety risk). Since combustibles are undesirable in the offgas, while the presence of unreacted oxygen there presents minimal safe and environmental concerns, the starting time principle of combustion management is to provide more than oxygen than is theoretically needed to ensure that all the fuel burns. For methane (CH

4 ) combustion, for example, slightly more than than 2 molecules of oxygen are required.

The second principle of combustion management, however, is to not apply too much oxygen. The correct amount of oxygen requires three types of measurement: first, active control of air and fuel flow; second, offgas oxygen measurement; and 3rd, measurement of offgas combustibles. For each heating process, in that location exists an optimum status of minimal offgas rut loss with acceptable levels of combustibles concentration. Minimizing excess oxygen pays an boosted benefit: for a given offgas temperature, the NOx level is lowest when excess oxygen is kept lowest.[3]

Adherence to these two principles is furthered by making fabric and rut balances on the combustion process.[xviii] [19] [twenty] [21] The material balance directly relates the air/fuel ratio to the percentage of O

2 in the combustion gas. The heat balance relates the heat available for the charge to the overall net heat produced by fuel combustion.[22] [23] Additional material and oestrus balances can be made to quantify the thermal advantage from preheating the combustion air,[24] [25] or enriching information technology in oxygen.[26] [27]

Reaction machinery [edit]

Combustion in oxygen is a chain reaction in which many distinct radical intermediates participate. The high energy required for initiation is explained by the unusual structure of the dioxygen molecule. The everyman-energy configuration of the dioxygen molecule is a stable, relatively unreactive diradical in a triplet spin state. Bonding can be described with three bonding electron pairs and two antibonding electrons, with spins aligned, such that the molecule has nonzero total angular momentum. Nigh fuels, on the other hand, are in a singlet state, with paired spins and zero total angular momentum. Interaction betwixt the 2 is quantum mechanically a "forbidden transition", i.e. possible with a very depression probability. To initiate combustion, free energy is required to force dioxygen into a spin-paired land, or singlet oxygen. This intermediate is extremely reactive. The free energy is supplied as oestrus, and the reaction then produces additional heat, which allows information technology to continue.

Combustion of hydrocarbons is thought to be initiated past hydrogen atom abstraction (not proton abstraction) from the fuel to oxygen, to give a hydroperoxide radical (HOO). This reacts further to give hydroperoxides, which break up to requite hydroxyl radicals. There are a great diverseness of these processes that produce fuel radicals and oxidizing radicals. Oxidizing species include singlet oxygen, hydroxyl, monatomic oxygen, and hydroperoxyl. Such intermediates are curt-lived and cannot be isolated. All the same, non-radical intermediates are stable and are produced in incomplete combustion. An example is acetaldehyde produced in the combustion of ethanol. An intermediate in the combustion of carbon and hydrocarbons, carbon monoxide, is of special importance because it is a poisonous gas, simply too economically useful for the production of syngas.

Solid and heavy liquid fuels also undergo a great number of pyrolysis reactions that give more easily oxidized, gaseous fuels. These reactions are endothermic and require constant free energy input from the ongoing combustion reactions. A lack of oxygen or other improperly designed weather result in these noxious and carcinogenic pyrolysis products being emitted as thick, black smoke.

The rate of combustion is the amount of a material that undergoes combustion over a menstruation of fourth dimension. It can exist expressed in grams per second (yard/s) or kilograms per second (kg/southward).

Detailed descriptions of combustion processes, from the chemic kinetics perspective, requires the formulation of large and intricate webs of elementary reactions.[28] For case, combustion of hydrocarbon fuels typically involve hundreds of chemical species reacting according to thousands of reactions.

Inclusion of such mechanisms inside computational menses solvers however represents a pretty challenging task mainly in 2 aspects. Kickoff, the number of degrees of freedom (proportional to the number of chemical species) tin can be dramatically large; second, the source term due to reactions introduces a disparate number of fourth dimension scales which makes the whole dynamical organization strong. As a event, the straight numerical simulation of turbulent reactive flows with heavy fuels before long becomes intractable fifty-fifty for modern supercomputers.[29]

Therefore, a plethora of methodologies has been devised for reducing the complexity of combustion mechanisms without resorting to loftier detail level. Examples are provided past:

- The Relaxation Redistribution Method (RRM)[30] [31] [32] [33]

- The Intrinsic Depression-Dimensional Manifold (ILDM) arroyo and further developments[34] [35] [36]

- The invariant constrained equilibrium edge preimage curve method.[37]

- A few variational approaches[38] [39]

- The Computational Singular perturbation (CSP) method and farther developments.[40] [41]

- The Rate Controlled Constrained Equilibrium (RCCE) and Quasi Equilibrium Manifold (QEM) approach.[42] [43]

- The Yard-Scheme.[44]

- The Method of Invariant Grids (MIG).[45] [46] [47]

Kinetic modelling [edit]

The kinetic modelling may be explored for insight into the reaction mechanisms of thermal decomposition in the combustion of different materials past using for example Thermogravimetric analysis.[48]

Temperature [edit]

Antoine Lavoisier conducting an experiment related to combustion generated past amplified lord's day low-cal.

Assuming perfect combustion weather condition, such as complete combustion nether adiabatic conditions (i.e., no heat loss or gain), the adiabatic combustion temperature can exist determined. The formula that yields this temperature is based on the showtime law of thermodynamics and takes annotation of the fact that the heat of combustion is used entirely for heating the fuel, the combustion air or oxygen, and the combustion product gases (commonly referred to every bit the flue gas).

In the instance of fossil fuels burnt in air, the combustion temperature depends on all of the following:

- the heating value;

- the stoichiometric air to fuel ratio ;

- the specific oestrus capacity of fuel and air;

- the air and fuel inlet temperatures.

The adiabatic combustion temperature (also known every bit the adiabatic flame temperature) increases for higher heating values and inlet air and fuel temperatures and for stoichiometric air ratios approaching ane.

Virtually unremarkably, the adiabatic combustion temperatures for coals are around ii,200 °C (3,992 °F) (for inlet air and fuel at ambient temperatures and for ), effectually 2,150 °C (3,902 °F) for oil and 2,000 °C (iii,632 °F) for natural gas.[49] [50]

In industrial fired heaters, ability station steam generators, and large gas-fired turbines, the more than common way of expressing the usage of more than than the stoichiometric combustion air is percentage excess combustion air. For instance, backlog combustion air of xv percent means that 15 percent more than the required stoichiometric air is being used.

Instabilities [edit]

Combustion instabilities are typically trigger-happy pressure oscillations in a combustion chamber. These pressure oscillations can exist as high as 180dB, and long-term exposure to these cyclic pressure and thermal loads reduce the life of engine components. In rockets, such equally the F1 used in the Saturn 5 program, instabilities led to massive damage to the combustion chamber and surrounding components. This trouble was solved by re-designing the fuel injector. In liquid jet engines, the droplet size and distribution can be used to benumb the instabilities. Combustion instabilities are a major business in footing-based gas turbine engines considering of NOx emissions. The tendency is to run lean, an equivalence ratio less than 1, to reduce the combustion temperature and thus reduce the NOten emissions; however, running the combustion lean makes it very susceptible to combustion instability.

The Rayleigh Criterion is the basis for analysis of thermoacoustic combustion instability and is evaluated using the Rayleigh Index over one wheel of instability[51]

where q' is the rut release rate perturbation and p' is the pressure level fluctuation.[52] [53] When the heat release oscillations are in phase with the pressure oscillations, the Rayleigh Alphabetize is positive and the magnitude of the thermo acoustic instability is maximised. On the other paw, if the Rayleigh Alphabetize is negative, and so thermoacoustic damping occurs. The Rayleigh Criterion implies that a thermoacoustic instability tin can be optimally controlled by having heat release oscillations 180 degrees out of phase with pressure oscillations at the aforementioned frequency.[54] [55] This minimizes the Rayleigh Index.

Meet also [edit]

References [edit]

- ^ colloquial pregnant of burning is combustion accompanied by flames

- ^ a b Schmidt-Rohr, K (2015). "Why Combustions Are Always Exothermic, Yielding Well-nigh 418 kJ per Mole of O2". J. Chem. Educ. 92 (12): 2094–2099. Bibcode:2015JChEd..92.2094S. doi:10.1021/acs.jchemed.5b00333.

- ^ a b The formation of NOx. Alentecinc.com. Retrieved on 2010-09-28.

- ^ "Incomplete combustion procedure".

- ^ "Burning showing incomplete combustion".

- ^ a b "Environmental Problems associated with incomplete combustion".

- ^ "Carbon Monoxide Poisoning". 8 December 2020.

- ^ "A Perfect Storm: Mulch Burn down Dynamics and Prevention". Soilandmulchproducernews.com. Retrieved 2018-07-12 .

- ^ Shuttle-Mir History/Science/Microgravity/Candle Flame in Microgravity (CFM) – MGBX. Spaceflight.nasa.gov (1999-07-sixteen). Retrieved on 2010-09-28.

- ^ [ane] Equilib-Web

- ^ ASM Commission on Furnace Atmospheres, Furnace atmospheres and carbon control, Metals Park, OH [1964].

- ^ "Exothermic atmospheres". Industrial Heating: 22. June 2013. Retrieved 5 July 2013.

- ^ [ii] ExoCalc

- ^ "Reaction-Web". Crct.polymtl.ca. Retrieved 2018-07-12 .

- ^ a b Bradley, D (2009-06-25). "Combustion and the design of hereafter engine fuels". Proceedings of the Institution of Mechanical Engineers, Office C: Journal of Mechanical Engineering Science. 223 (12): 2751–2765. doi:x.1243/09544062jmes1519. S2CID 97218733.

- ^ "Computing the rut of combustion for natural gas". Industrial Heating: 28. September 2012. Retrieved 5 July 2013.

- ^ [iii] HeatCalc

- ^ "Making a cloth residue". Industrial Heating: twenty. November 2012. Retrieved 5 July 2013.

- ^ [4] MatBalCalc

- ^ "Making a heat balance". Industrial Heating: 22. December 2012. Retrieved v July 2013.

- ^ [5] HeatBalCalc

- ^ "Available combustion heat". Industrial Heating: 22. April 2013. Retrieved five July 2013.

- ^ [6] AvailHeatCalc

- ^ "Making a system balance (Part 2)". Industrial Heating: 24. March 2012. Retrieved v July 2013.

- ^ [7] SysBalCalc2

- ^ "Making a organisation rest (Part 1)". Industrial Heating: 22. February 2012. Retrieved 5 July 2013.

- ^ [8] SysBalCalc

- ^ Police force, C.K. (2006). Combustion Physics. Cambridge, UK: Cambridge University Press. ISBN9780521154215.

- ^ Goussis, D.; Maas, U. (2011). Turbulent Combustion Modeling. Springer Science. pp. 193–220.

- ^ Chiavazzo, Eliodoro; Karlin, Ilya (2011). "Adaptive simplification of complex multiscale systems". Phys. Rev. East. 83 (iii): 036706. arXiv:1011.1618. Bibcode:2011PhRvE..83c6706C. doi:x.1103/PhysRevE.83.036706. PMID 21517624. S2CID 7458232.

- ^ Chiavazzo, Eliodoro; Asinari, Pietro; Visconti, Filippo (2011). "Fast ciphering of multi-calibration combustion systems". Phil. Trans. Roy. Soc. A. 369 (1945): 2396–2404. arXiv:1011.3828. Bibcode:2011RSPTA.369.2396C. doi:x.1098/rsta.2011.0026. PMID 21576153. S2CID 14998597.

- ^ Chiavazzo, Eliodoro (2012). "Approximation of slow and fast dynamics in multiscale dynamical systems by the linearized Relaxation Redistribution Method". Journal of Computational Physics. 231 (4): 1751–1765. arXiv:1102.0730. Bibcode:2012JCoPh.231.1751C. doi:x.1016/j.jcp.2011.11.007. S2CID 16979409.

- ^ Kooshkbaghi, Mahdi; Frouzakis, E. Christos; Chiavazzo, Eliodoro; Boulouchos, Konstantinos; Karlin, Ilya (2014). "The global relaxation redistribution method for reduction of combustion kinetics" (PDF). The Periodical of Chemical Physics. 141 (4): 044102. Bibcode:2014JChPh.141d4102K. doi:ten.1063/1.4890368. PMID 25084876.

- ^ Maas, U.; Pope, S.B. (1992). "Simplifying chemic kinetics: intrinsic low-dimensional manifolds in composition space". Combust. Flame. 88 (iii–4): 239–264. doi:10.1016/0010-2180(92)90034-one thousand.

- ^ Bykov, V.; Maas, U (2007). "The extension of the ILDM concept to reaction–improvidence manifolds". Combust. Theory Model. 11 (6): 839–862. Bibcode:2007CTM....eleven..839B. doi:10.1080/13647830701242531. S2CID 120624915.

- ^ Nafe, J.; Maas, U. (2002). "A general algorithm for improving ILDMs". Combust. Theory Model. 6 (4): 697–709. Bibcode:2002CTM.....vi..697N. doi:10.1088/1364-7830/six/4/308. S2CID 120269918.

- ^ Ren, Z.; Pope, S.B.; Vladimirsky, A.; Guckenheimer, J.Thousand. (2006). "The invariant constrained equilibrium edge preimage curve method for the dimension reduction of chemical kinetics". J. Chem. Phys. 124 (11): 114111. Bibcode:2006JChPh.124k4111R. doi:10.1063/i.2177243. PMID 16555878.

- ^ Lebiedz, D (2010). "Entropy-related extremum principles for model reduction of dissipative dynamical systems". Entropy. 12 (4): 706–719. Bibcode:2010Entrp..12..706L. doi:10.3390/e12040706.

- ^ Reinhardt, V.; Winckler, Chiliad.; Lebiedz, D. (112). "Approximation of ho-hum alluring manifolds in chemical kinetics by tra trjectory-based optimization approaches" (PDF). J. Phys. Chem. A. 112 (viii): 1712–1718. Bibcode:2008JPCA..112.1712R. doi:x.1021/jp0739925. PMID 18247506.

- ^ Lam, S.H.; Goussis, D. (1991). Conventional Asymptotic and Computational Singular Perturbation for Symplified Kinetics Modelling. Berlin: Springer.

- ^ Valorani, M.; Goussis, D.; Najm, H.N. (2005). "College order corrections in the approximation of depression-dimensional manifolds and the construction of simplified issues with the csp method". J. Comput. Phys. 209 (2): 754–786. Bibcode:2005JCoPh.209..754V. doi:x.1016/j.jcp.2005.03.033.

- ^ Keck, J.C.; Gillespie, D. (1971). "Rate-controlled partial-equilibrium method for treating reacting gas mixtures". Combust. Flame. 17 (2): 237–241. doi:10.1016/S0010-2180(71)80166-9.

- ^ Chiavazzo, Eliodoro; Karlin, Ilya (2008). "Quasi-equilibrium grid algorithm: geometric construction for model reduction". J. Comput. Phys. 227 (11): 5535–5560. arXiv:0704.2317. Bibcode:2008JCoPh.227.5535C. doi:10.1016/j.jcp.2008.02.006. S2CID 973322.

- ^ Valorani, One thousand.; Paolucci, S. (2009). "The G-Scheme: a framework for multi-scale adaptive model reduction". J. Comput. Phys. 228 (thirteen): 4665–4701. Bibcode:2009JCoPh.228.4665V. doi:ten.1016/j.jcp.2009.03.011.

- ^ Chiavazzo, Eliodoro; Karlin, Ilya; Gorban, Alexander (2010). "The role of thermodynamics in model reduction when using invariant grids" (PDF). Commun. Comput. Phys. 8 (4): 701–734. Bibcode:2010CCoPh...8..701C. CiteSeerX10.1.1.302.9316. doi:10.4208/cicp.030709.210110a.

- ^ Chiavazzo, Eliodoro; Karlin, Ilya; Frouzakis, Christos Eastward.; Boulouchos, Konstantinos (2009). "Method of invariant grid for model reduction of hydrogen combustion". Proceedings of the Combustion Institute. 32: 519–526. arXiv:0712.2386. doi:10.1016/j.proci.2008.05.014. S2CID 118484479.

- ^ Chiavazzo, Eliodoro; Karlin, Ilya; Gorban, Alexander; Boulouchos, Konstantinos (2010). "Coupling of the model reduction technique with the lattice Boltzmann method for combustion simulations". Combust. Flame. 157 (ten): 1833–1849. doi:10.1016/j.combustflame.2010.06.009.

- ^ Reyes, J.A.; Conesa, J.A.; Marcilla, A. (2001). "Pyrolysis and combustion of polycoated cartons recycling. kinetic model and ms analysis". Journal of Belittling and Applied Pyrolysis. 58–59: 747–763. doi:ten.1016/S0165-2370(00)00123-6.

- ^ "Adiabatic flame temperature". Industrial Heating: xx. May 2013. Retrieved 5 July 2013.

- ^ [9] AFTCalc

- ^ John William Strutt, 3rd Baron Rayleigh, Sc.D., F.R.S.., Honorary Fellow of Trinity Higher, Cambridge; "The Theory of Sound", §322h, 1878:

- ^ A. A. Putnam and Westward. C. Dennis (1953) "Organ-pipe oscillations in a flame-filled tube," Quaternary Symposium (International) on Combustion, The Combustion Establish, pp. 566–574.

- ^ E. C. Fernandes and M. V. Heitor, "Unsteady flames and the Rayleigh criterion" in F. Culick, M. Five. Heitor, and J. H. Whitelaw, ed.south, Unsteady Combustion (Dordrecht, the Netherlands: Kluwer Academic Publishers, 1996), p. 4

- ^ Dowling, A. P. (2000a). "Vortices, audio and flame – a damaging combination". The Aeronautical Journal of the RaeS

- ^ Chrystie, Robin S. M.; Burns, Iain S.; Kaminski, Clemens F. (2013). "Temperature Response of an Acoustically Forced Turbulent Lean Premixed Flame: A Quantitative Experimental Determination". Combustion Science and Engineering science. 185: 180–199. doi:ten.1080/00102202.2012.714020. S2CID 46039754.

Further reading [edit]

| | Look up combustion in Wiktionary, the free lexicon. |

- Poinsot, Thierry; Veynante, Denis (2012). Theoretical and Numerical Combustion (3rd ed.). European Centre for Research and Advanced Training in Scientific Ciphering.

- Lackner, Maximilian; Wintertime, Franz; Agarwal, Avinash K., eds. (2010). Handbook of Combustion, five volume set. Wiley-VCH. ISBN978-3-527-32449-1.

- Baukal, Charles E., ed. (1998). Oxygen-Enhanced Combustion. CRC Press.

- Glassman, Irvin; Yetter, Richard. Combustion (Fourth ed.).

- Turns, Stephen (2011). An Introduction to Combustion: Concepts and Applications.

- Ragland, Kenneth W; Bryden, Kenneth K. (2011). Combustion Engineering (Second ed.).

- Baukal, Charles E. Jr, ed. (2013). "Industrial Combustion". The John Zink Hamworthy Combustion Handbook: Iii-Volume Set (Second ed.).

- Gardiner, W. C. Jr (2000). Gas-Phase Combustion Chemistry (Revised ed.).

Source: https://en.wikipedia.org/wiki/Combustion

0 Response to "in order for combustion to occur what needs to happen"

Post a Comment